Science for product makers: Why stable cannabis emulsion can’t guarantee stable infused beverages

Last week I asked my followers what they think is the most important factor for cannabis beverage potency stability. Most people selected “infusion...

Have you ever thought about what’s in that aluminum can you’re drinking out of? Well, other than the calories or sugar content of your beverage of choice. No? You’re definitely not alone. But did you know that the aluminum can is actually one of the most engineered products of the 20th century, and considered a modern marvel by many? Yes, really.

Can liners provide challenges every step of the way for product makers - from manufacturing process issues and impacts on flavor to potential corrosion and the preservation of the product’s shelf life. Even more importantly, cannabinoid potency loss has plagued the infused beverage industry since its inception. Scientists have spent countless hours trying to overcome this technical challenge that everyday consumers don’t even think about.

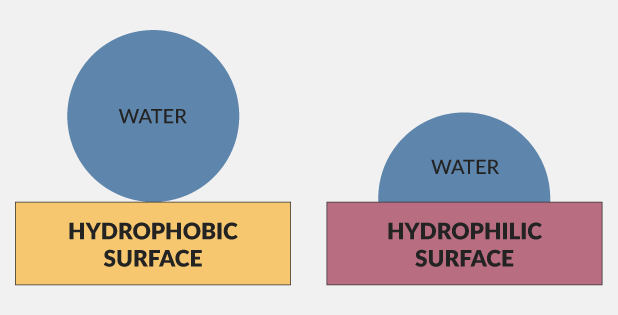

To understand this ongoing problem on a larger scale, we first have to break down the chemistry process at work. Two terms are essential to understand: hydrophilic and hydrophobic.

Hydrophilic means molecules get along with water, while hydrophobic means the molecules don’t get along with water. The aluminum that cans are made from is hydrophilic, meaning it attracts and interacts with water easily. This sounds preferable, but when the goal is to preserve the integrity of the liquid inside a can, you actually need the can itself to repel the liquid. Doing so will prevent the undesirable effects we mentioned earlier - corrosion, flavor interference, and stability.

As such, aluminum cans are actually coated on the inside with a hydrophobic layer of thin polymer that serves the purpose of keeping the liquid away from the aluminum. Turns out there’s a lot more than just aluminum in that can you’re drinking!

The problem with cannabinoid potency loss in aluminum cans lies once again in the molecular details. The polymer liner is hydrophobic, and a cannabis emulsion droplet, which contains oil in its core, is also hydrophobic. Under pressure, the hydrophobic liner will attract the hydrophobic emulsion droplet and attach it to the liner over time. This creates problems much greater than altering the flavor of the beverage; can liners can cause the potency of the beverage to decrease over time. With this loss of potency in infused beverages, your consumers won’t be receiving a consistent dose as advertised on your can. In many cases, the product may need to be relabelled, or worse, recalled entirely.

Once we learned about this issue, Vertosa partnered up with top aluminum can manufacturers including Ball, Ardagh, and Gamer to test for a possible solution to potency loss.

Over the past year, we ran an exhaustive study encompassing 11 rounds of testing, utilizing 21 distinct emulsion formulas within eight different can liners. We’ve accumulated the findings from each round and utilized the results to fortify our emulsions for ultimate compatibility with the different can liner types.

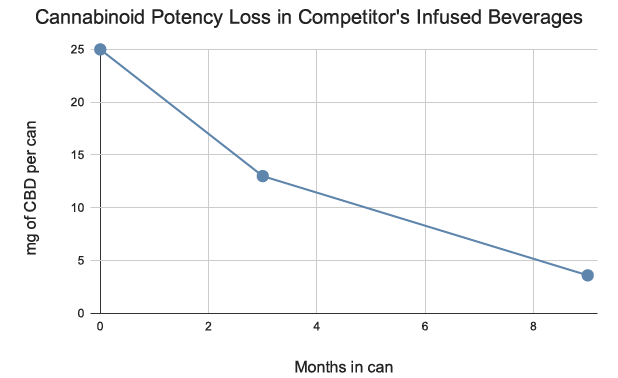

Comparing these low potency losses to our competitors, the difference is staggering. At just 3 months on the shelf, a major competitor's product tested at almost half of it's advertised potency. Further, that same product was tested indicating more than an 85% loss in cannabinoid potency over 9 months on the shelf.

With all of our clients, we strongly encourage all products to undergo a pilot study with us and our third-party labs to monitor the stability of the product over time. This enables us to deliver clear evidentiary data that their specific product is stable within a can. Contact us below to get started with a Vertosa pilot study today!

Last week I asked my followers what they think is the most important factor for cannabis beverage potency stability. Most people selected “infusion...

This post was originally published on August 9, 2024, as an article on Harold's LinkedIn profile. You can read and leave comments here.

This post is also published as an article on Harold's LinkedIn profile. You can read and leave comments here.